Thermal Imaging for Mechanical Maintenance: Why Pros Choose Ti240

In industrial environments, mechanical equipment like motors, pumps, gearboxes, bearings, and conveyor systems runs continuously under heavy loads. Unplanned downtime from overheating, friction, misalignment, or lubrication failure can cost thousands per hour. Thermal imaging has become a cornerstone of predictive maintenance programs because it detects temperature anomalies early — often weeks or months before vibration or oil analysis flags the issue.

The HANMATEK Ti240 — a rugged, high-resolution handheld thermal camera — is increasingly the tool of choice for maintenance professionals who need fast, reliable, and detailed thermal scans without the high cost of premium brands.

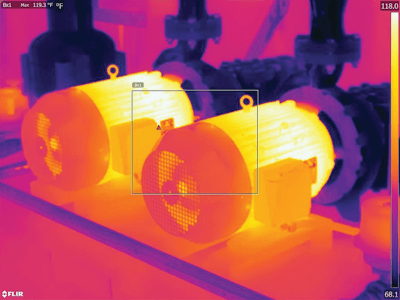

Here are real-world thermal images showing overheating bearings and motors in industrial machinery, captured with high-resolution thermal cameras:

Key Mechanical Issues Detected with Thermal Imaging

Overheated Bearings & Friction Bearings generate heat from wear, lack of lubrication, or contamination. The Ti240's 240×240 resolution (57,600 measurement points) and ≤60 mK thermal sensitivity reveal small hot spots that lower-resolution cameras blur, allowing technicians to schedule lubrication or replacement before failure.

-

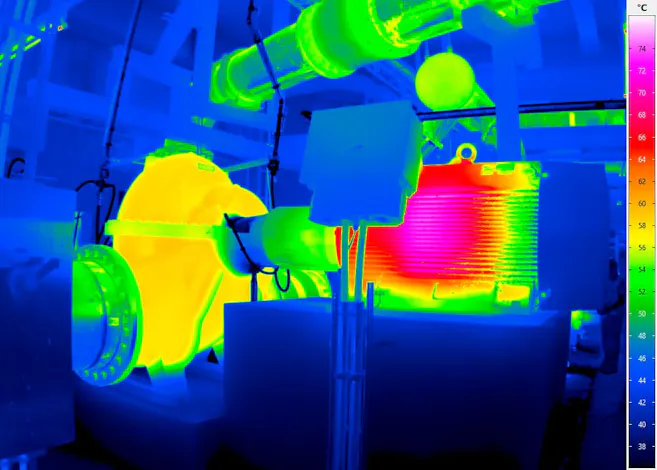

Motor & Drive Problems Overloaded windings, faulty insulation, or unbalanced loads show as uneven heating. Scan entire motors and gearboxes quickly to spot anomalies.

Thermal scans of motors and gearboxes highlighting hot spots from misalignment or overload:

- Pump & Compressor Efficiency Blocked impellers, cavitation, or seal failures appear as localized hot zones. The Ti240's wide -20°C to 550°C range covers both cold suction sides and hot discharge areas.

- Belt Drives, Couplings & Conveyors Misalignment or slippage generates friction heat. The 25 Hz refresh rate ensures smooth scanning of moving components.

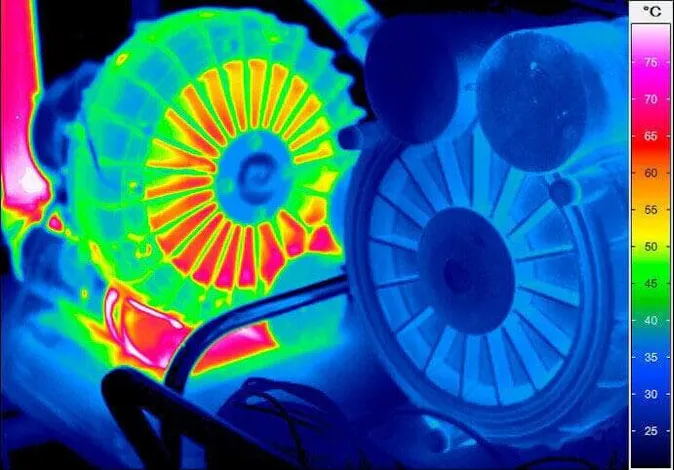

- Gearboxes & Transmission Systems Early wear, inadequate lubrication, or gear tooth issues show up as temperature gradients — often before audible noise or vibration spikes.

Professionals in action using handheld thermal cameras on industrial gearboxes, pumps, and conveyor systems during routine maintenance:

Why Maintenance Teams Prefer the HANMATEK Ti240

- High 240×240 Resolution — Sharper detail than 120×90 or 160×120 models for pinpointing small mechanical anomalies.

- Fast & Intuitive Operation — 6 color palettes, high/low alarms, and visible-light fusion help quickly identify and document issues.

- Rugged & Reliable — IP54 dust/splash resistance, 1.5m drop protection, and 9-hour battery life for full-shift use in harsh factory conditions.

- Professional Reporting — Photo/video capture, 8GB SD card, and PC software support for PdM reports and trend tracking.

- Outstanding Value — Delivers pro-grade performance at a fraction of the cost of legacy brands.

Integrate the Ti240 into your predictive maintenance routine to reduce unplanned downtime, extend equipment life, and lower repair costs.

Ready to enhance your mechanical maintenance program?

Shop the HANMATEK Ti240 Thermal Camera now and see the difference high-resolution thermal imaging makes: Buy HANMATEK Ti240 Thermal Camera

Explore more new arrivals: New Arrival HANMATEK Tools Collection

Catch problems before they stop production — with the Ti240.

Einen Kommentar hinterlassen